Superhumans with Superhealth

Making health super fun, super creative, and super innovative, secondary school students are thinking about how they can transform healthcare as part of programs run by Monash Tech School.

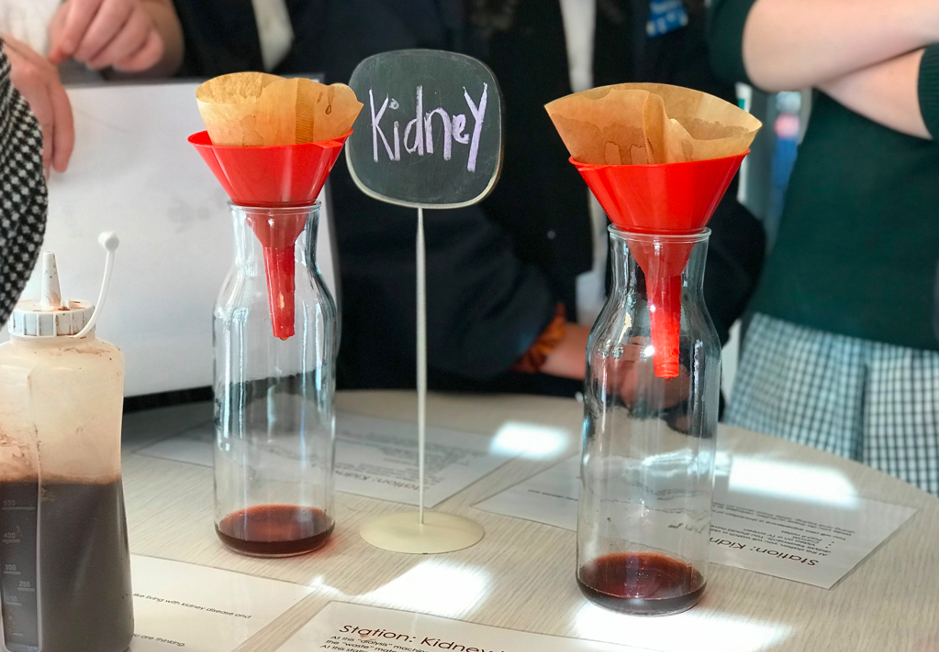

In the Superhumans program, Year 7 students work in teams to design implants, smart clothing, wearables and bionic devices for patients with various impediments or diseases. Teams research a medical condition and use case studies and props to put themselves in the shoes of those living with it to better understand patient needs. Students are challenged to brainstorm ideas, thinking about ways that medical devices, such as implants and bionics, might provide benefits. They undergo a “design-thinking” process – blending creativity with problem-solving. No idea is too wild.

Similar to research teams in the medical technology (MedTech) industry, Monash Tech School emphasises the importance of people with different skillsets coming together to work on a project. No one person is an expert in everything, and research groups are becoming increasingly multi-disciplinary. Within their teams, students are allocated roles and investigate the problem from different angles (e.g. the electronics side or the intricacies of human anatomy). With electronics, microscopes, 3-D printers, a laser cutter, and a materials library at their disposal, the sky is the limit.

By the end of the program, student teams build a model prototype and pitch it to the audience, thinking about who they might be selling their product to (e.g. patients or doctors). One group of students from Wellington Secondary College designed and pitched a device to replace a faulty heart valve. The team created a prototype with Lego and then a 3-D printed model of their valve replacement that could fit inside a heart. Another group of students created an eye pump system for glaucoma patients. Vision loss in glaucoma is usually caused by the eye’s drainage system becoming clogged so that fluid builds up in the eye and causes damage to nerve fibres. Students pitched a bionic device drainage pump to drain fluid, alleviating pressure in the eye, and on the sensitive nerves, in particular, to restore vision.

‘Building on real science, the students’ devices can get complex, quite advanced, and very impressive,’ says Tori Brewster, Program Facilitator.

In the Superhealth program, Year 9 students take a more overarching approach to healthcare. Their challenge is to create visions of future hospitals, learning from the experiences of professionals currently working in the healthcare sector to inform their own hospital designs. Part of the program involves thinking about the best way to diagnose diseases and find the most effective treatments. Students go into a lab where there look at microscopy slides of patient samples and identify signs of disease pathology – but they soon realise that this alone is not enough to decide on a treatment.

Students are introduced to the idea of personalised healthcare based on the genetics of disease. They analyse mock patient DNA samples using Bento Lab boxes – devices that function as a portable molecular biology lab, combining five pieces of scientific equipment into one. By amplifying and visualising DNA samples, they can tell what type of cancer a patient has, what bacteria a patient is infected with, etc. by looking for specific genetic markers.

Jumping into the industry side of healthcare, students also learn about the production of therapeutics (e.g. insulin, therapeutic antibodies, etc.). To make large batches of proteins, the biotechnology industry makes use of bacteria and yeast that reproduce in large numbers. The bacterium E.coli, for example, reproduces every 20 minutes, and can therefore be manipulated to produce an exponentially increasing amounts of protein once given the genetic instructions to make a given protein. Students try their hands at genetic engineering themselves, introducing the “green fluorescent protein” gene (typically used in biotechnology to track gene expression) into E.coli, making the bacteria glow green under ultraviolet light.

Students get hands-on with equipment, encouraging tactile learning and sparking an interest in STEM among some students who had not previously considered it. The genetic engineering and biotechnology experiments performed by students in the program are typically not covered until second or third year of an undergraduate university degree. But under the guidance of Monash Tech School staff, they successfully complete all tasks. ‘This proves that biotechnology is not beyond secondary students,’ says Andrew Gray, Lab Facilitator.

Monash Tech School programs build and elevate technology and innovation skills in the next generation of students going into STEM. They also foster communication, teamwork and project management acumen by challenging students to collaborate in interdisciplinary teams to ideate, prototype and pitch a solution. Students are encouraged to dream big in their design-thinking process and a large emphasis is placed on creativity. ‘If we want solutions of the future, we need that creativity,’ says Tori, and some of the ideas may evolve to take their place in the MedTech industry in years to come.

Catriona Nguyen-Robertson