Solving real-world problems, one step at a time

It’s “choose your own adventure” at Casey Tech School. Year 9-10 students are faced with real-world industry problems to solve in three days as part of Casey Tech School’s Enterprise Program. Students have the opportunity to work with industry-grade equipment to create a solution. They develop both STEAM (science, technology, engineering, art, and mathematics) and enterprise skills as they collaborate with peers and industry partners, engage in design thinking, build prototypes and, finally, pitch and market their solution.

At the beginning of the program, students select the question they want to tackle:

- How can the Casey Council encourage and support local residents and industries to use sustainable materials and practices to reduce landfill?

- How can we use robotics to aid the rehabilitation of patients to enhance the recovery process?

- How can the National Disability Insurance Scheme (NDIS) provide support that is environmentally sustainable?

- How can virtual reality (VR) be used to empower young Australians to be more mindful of their health and wellbeing?

- And a question that no one guessed would be quite so relevant at the time – How can the City of Casey maintain personal and economic health and wellbeing in the event of a pandemic?[1]

While it might not be feasible for students to solve the whole, broad problem in a matter of days, they can certainly make headway.

‘The five problems are easily split into 10-20 smaller problems, and we give students agency to choose how they will go about it,’ says Helen Silvester, Casey Tech School Director.

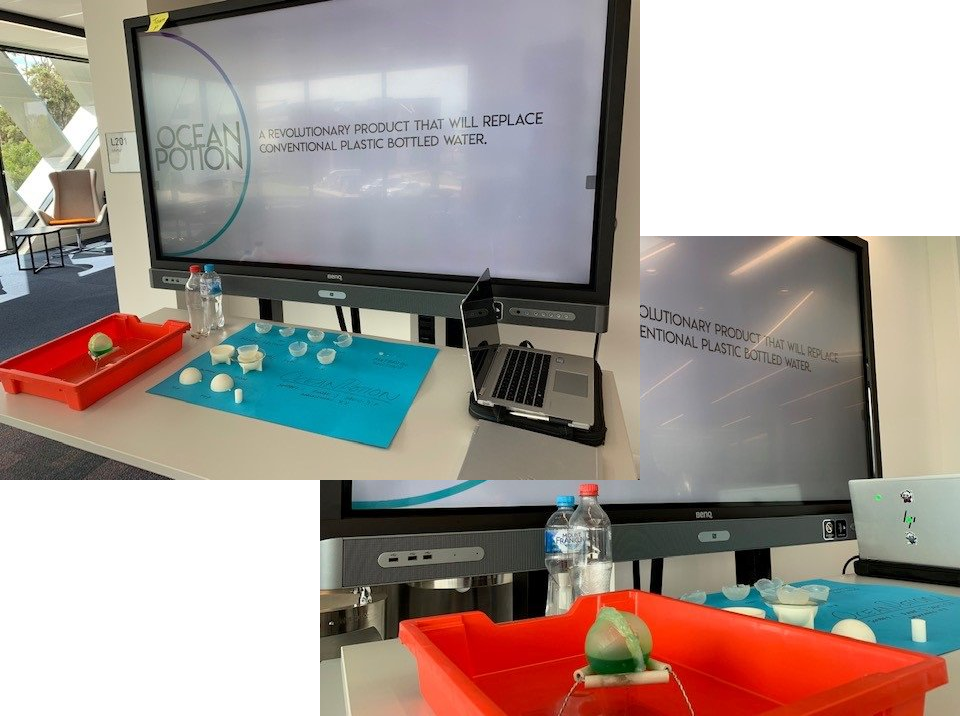

The workshops begin with generalised masterclasses for students to build their STEAM, project management, and pitching skills. They learn the basics of innovative technologies and advanced manufacturing, such as virtual reality (VR), bioplastics production, electronics, coding software (Hummingbird and Arduino), and Computer-Aided Design for 3D-printing.

Armed with their newly acquired skills, students draw up a design brief in small teams and then ideate their solution. They move in and out of the different workspaces and labs for two days to perfect what they need to in order to create prototypes. If something fails, they can tweak it to make it better the next time.

‘It’s just like a real workplace’, says Helen. ‘It’s all about learning that you’re not always going to succeed the first time. But if you don’t try, you will definitely fail.’

One of the more common techniques adopted by students is using 3D-printing to create prototypes made from bioplastics. There are many types of plastic that come in all shapes and textures that are either synthetic or biobased.

Most common plastics are derived from crude oil, natural gas or coal. But the growing demand for limited oil-reserves, the need to reduce plastic pollution and waste, and the effort to be more sustainable has driven demand for biobased plastics made from renewable products such as cornflour, gelatine, vegetable fats and oils, etc. These plastics can be put into compost bins when no longer used, in contrast to synthetic plastics that are difficult to break down. In fact, some students produced a cling film style plastic wrap with embedded seeds that would grow plants when buried in the ground so that disposing of it would actually be beneficial to the environment.

In addition, in partnership with the St John of God Hospital, students aimed to improve healthcare for people living with disabilities. A team of students 3D-printed a plastic mouthguard that people without good hand mobility could bite down on to clean their teeth instead of brushing. Another group designed bathroom models that could easily be fitted into pre-existing bathrooms to support those who suddenly become disabled and need to modify their homes. Another team designed watches to monitor heart rate and transmit information to supervising medical professionals. The possibilities are endless.

Students also partnered with Global Wellness Tracking and St John of God Hospital to develop prototypes that specifically aid teenager wellbeing. Quickly learning coding skills, they designed ways to turn rehabilitation exercises into fun games or calming environments to escape from anxiety with virtual reality.

Months before it became standard, students also designed face masks that were “cool” to wear in case of a pandemic. They also tested materials to develop those that are resistant to microbes to reduce infectious disease transmission to be used on public transport, and coded robots to clean public areas. These solutions may have proven handy this year!

At the conclusion of the program, teams pitch and market their solution to their peers and industry partners. From the creative, innovative ideas that they come up with, their jobs would certainly be made easy!

The program provides students with insight into the advanced manufacturing and healthcare industries – both of which are prominent in the region with a forecast of strong growth. It also aims to equip them with skills and knowledge required to compete in the future global job market.

‘[The program] gives me the opportunity to experience new things and then have those experiences that I can put forward to jobs I might get in the future and opens so many doorways that I would never have had the chance to open,’ says a student from Narre Warren South P-12 College.

With the skills they gain over the course of their time at Casey Tech School and their brilliant ideas, these students undoubtedly have bright futures ahead of them.

Written by Catriona Nguyen-Robertson

[1] If you would like to read more about the Pandemic Preparedness Program, you can read an article posted by the Victorian Department of Education and Training here.